Youtube video link : https://youtube.com/shorts/UiX1_UVnWLw

PERFORMANCES AND FEATURES

◭The all-round wall scraping mixing adopts the frequency converter for speed adjustment , so that high quality products of different processes according to customer requirements.

◭The diversified high-speed homogenizer can powerfully mix solid and liquid raw materials and can rapidly dissolve manyindis soluble materials such as AES , AESA , LSA , etc. during the liquid detergent production process so as to save energy consumpion and shorten production period.

◭The pot body is welded by imported three-layer stainless steel plate. The tank body and the pipes adopt mittor polishing , which fully conforms to GMP requirements.

◭According to customer requirement , the tank can heat and cool materials. The heating way including steam heating and electric heating. Easy to discharge , bottom direct discharge or by transfer pump.

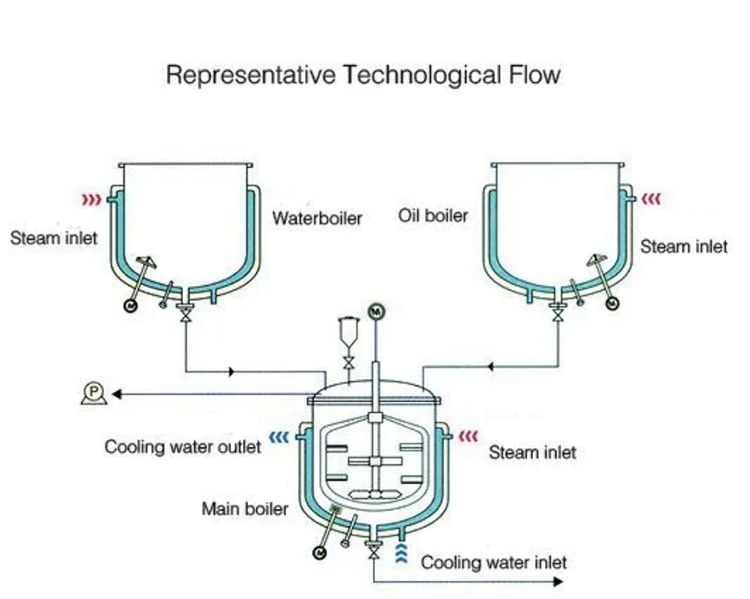

WORKING PROCESS

Put the materials into premix tank oil phase tank and water phase tank,after heated & mixed in water tank and oil tank, it can drawn the materials into emulsifying tank by vacuum pump. Adopting the middle stirrer & Teflon scrapers residues in emulsifying tank that sweep the residues on the wall of the tank to makes the materials wiped off become the new interface constantly. Then the materials will cut off, compressed and fold by the blades to stir, mix and run to the homogenizer. By the strong cutting off, impact and turbulent current from the high-speed shear wheel and fixed cutting case, the materials are cut off in interstices of stator and rotor and turn to particles of 6nm-2um promptly. Because the emulsifying tank is working under the vacuum state, the bubbles that produces in the process of mixing is taken away in time.

vacuum emulsifying mixer is widely use for below products:

- Cosmetic: face cream, hand cream, sunscreen cream, eyelash to cream, hair gel, lotion, bath shampoo, nail polish, hair conditioner etc.

- Pharmaceutical industry: ointments, syrup, nutrition, bio-products, paste of pharmaceutical etc.

- Daily use industry: toothpaste, detergents, shoes polish, soap, fragrance etc.

- Food industry: sauces, jam, chocolate, butter, vegetable proteins, animal proteins etc.

- Chemical industry: Painting, pigment, dyes, paints, adhesives detergents etc.

FAQ

1. main pot function : heating, frame scraper mixer, vacuum decrease bubble ,homogenizer ( high shear speed is important. )

heating: temperature meter automaticly control temperature when work set a temperature, such as 75 degree. It will automaticly heat to 75, and stop, if become lower, it will heat autoamticly again.

frame scraper mixer: with VFD to adjust speed

vacuum : vacuum decrease bubble.

homogenizer : high speed shear and emulsifying cream.

2. oil phase pot function : heating , impeller mixer

heating : It is the same as main pot , it has itself heating system and itself control system

impeller mixer: 0-1200RPM and adjust speed .

3. water phase pot function : heating , impeller mixer

heating : it is the same as main pot , it has itself heating system and itself control system

impeller mixer: 0-1200RPM and adjust speed .